Whitfield Welding Inc. has been specializing in high-value repair, refurbishment, and part enhancement since 1985. Our extensive experience in the automotive, oil and gas, energy, aerospace, and defense industries allows us to provide cutting edge solutions that are customized to each customer’s needs. We speak your language.

Experienced Service

Cutting Edge Facilities

Our facilities boast three specialized locations making us one of the largest and most complete complementary manufacturing partners in North America. Our working envelopes range from the microscopic, with parts weighing in grams, to macroscopic full-scale parts weighing in at 25 metric tons. Through our three shifts and our continuous investment in cutting edge technology, we continue to provide unmatched costs and lead times.

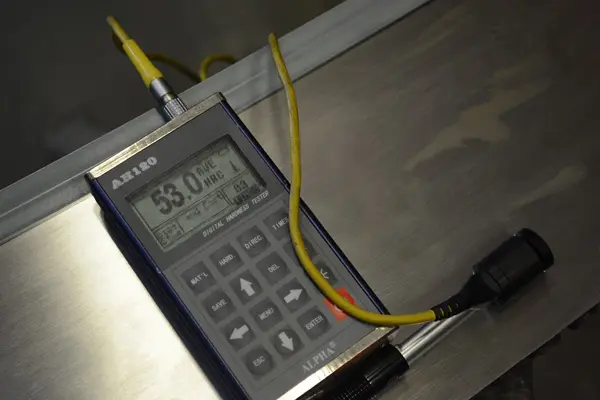

Our Dedication to Quality

Our high-end processes are ISO 9001 certified. Our quality team works closely with our metallurgical lab to maintain the highest standards demanded by industry. Between our testing of incoming material, our record keeping, and our in-process testing, we guarantee consistent accuracy as required by our customers.

Our goal is to provide customers with the best quality and service available in the welding industry. We specialize in high value component repair and refurbishment (TIG, Micro TIG, MIG), Micro Laser Welding, Laser Cladding, Laser Hardening, Laser Engraving, Stress Relief, Machining, and Metallurgical Lab Services.